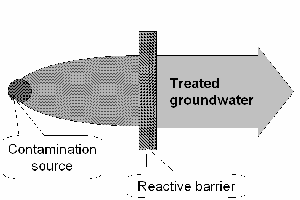

The method known since 1982 uses reactive materials placed in underground trenches downstream of the contamination plume forcing it to flow through them and by doing so, the contaminants are treated without soil or water excavation. PRB technology is based on the geochemical barrier principle: a change in the geochemical boundary conditions results in an enrichment of the chemical species and its degradation along the transport route. Precipitation of Fe(III)- and Mn(IV)-oxides or early diagenetic metal enrichment in aquatic sediments (manganese nodules formation on the seabed) are well-known products of geochemical barriers. The most commonly used immobilisation processes are: precipitation, sorption and biodegradation due to major changes in pH and redox potential. Main advantage of the geochemical barrier principle is a reduction in the operational costs which make up a considerable part of the overall costs. Amortisation of higher investment costs of geochemical barriers through lower operational costs generally depends on the reactivity and long-term behaviour of reactive materials.

Simon, F.-G., Meggyes, T., McDonald, C. (2002 - eds.): Advanced groundwater remediation. Active and passive technologies. London Thomas Telford. 2002 U.S. EPA, Technology Innovation Office (1996): A Citizen’s Guide to Treatment Walls. Solid Waste and Emergency Response (5102G): Rep. No. EPA 542-F-96-016.

Simon, F.-G.; Meggyes, T. (2000): Removal of organic and inorganic pollutants from groundwater using permeable reactive barriers. Part 1. Treatment processes for pollutants. Land Contamination & Reclamation 8 (2), pp 103-116

Meggyes, T.; Simon, F.-G. (2000): Removal of organic and inorganic pollutants from groundwater using permeable reactive barriers. Part 2. Engineering of permeable reactive barriers. Land Contamination & Reclamation 8 (3), pp 175-187